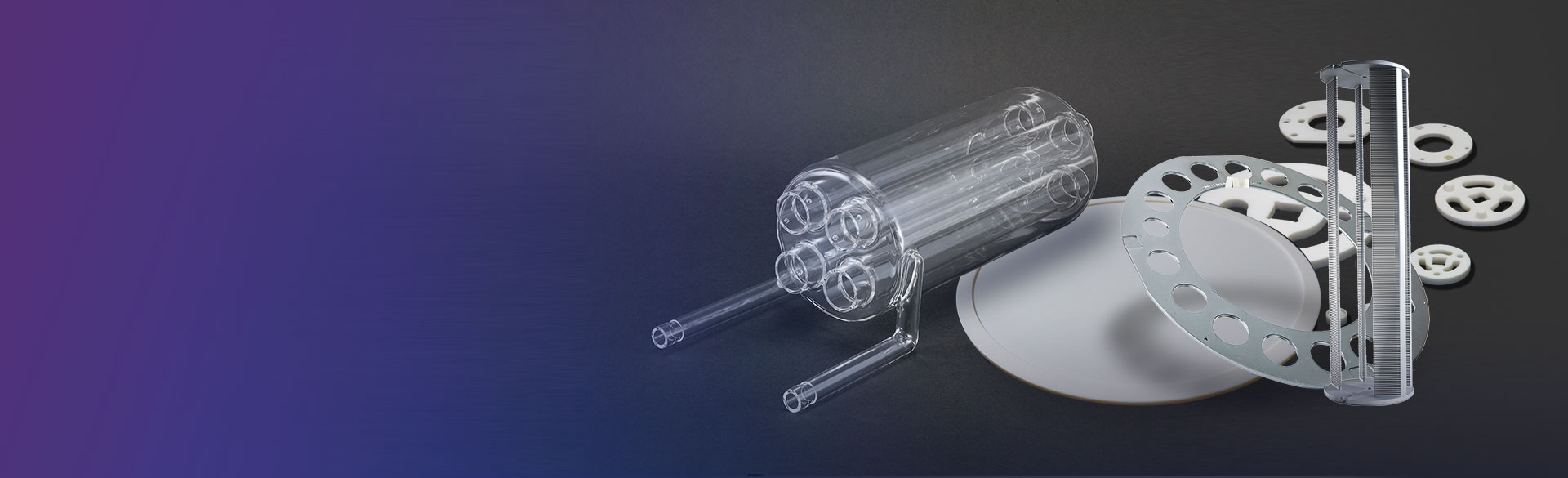

Ferrotec (China) has various advanced manufacturing facilities, such as precision MC centers, laser cutting, water jet cutting and LAP/POLISH machines, Class 10000 chemical cleaning room and Class 100 DIW cleaning room for precision quartz products. It can produce high volume quartz products for 12”, 8” and smaller size semiconductor applications, and also has the ability to develop the next generation 18” quartz products.

Ferrotec quartz factory is able to source appropriate raw materials in accordance with customers’ requirements. Major imported raw material materials are available including GE124/144/214/224(weakly alkaline) and GE244 (Low-Al) from Momentive, HSQ330/HSQ300/TSC-3 from Heraeus, OP-1/OP-3 from TOSOH Japan, and also QSIL PI/PN from Germany.

Equipped with many high precision inspection instruments,CMM, optical spectrum analyzers, projector, roughness meter, microscope, thickness gauge and etc.

It holds more than 200 high precision and high performance processing machines—such as, CNC machining center, CNC lathe, surface grinding machine, water jet cutting machine, laser cutting machine, multi-line cutting machine, band saw cutting machine, sleeve cutting machine, cylinder machine, centerless grinding machine (OD) and rotary machine. Meanwhile, Ferrotec self-develops several automatic cleaning lines (one is currently the most advanced automatic cleaning line around the world) and some automatic flame-polishing machines.